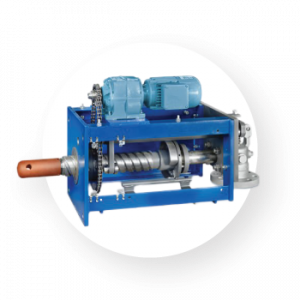

Currently over 85% of the world’s SCR reactors are cleaned using Clyde Industries technology, making Clyde Industries the undisputed leader in SCR cleaning systems worldwide. This remarkable industry leadership is due to our unique catalytic cleaning device, designed in partnership with catalyst providers, that optimizes cleaning without damaging the catalyst making it the perfect choice for new SCRs or to replace ineffective sonic horns.

The Rake Sootblower is designed to clean finned heating surfaces, rotating basket-type air heaters, economizers and DeNOx systems at flue gas temperatures less than 1292°F. The Rake Sootblower uses the potential energy in the blowing medium (either steam or air) and transforms it almost entirely into kinetic energy by means of venturi nozzles. Following this design, the sootblower uses a specially devised non-rotating lance to apply all cleaning power down towards the catalyst surface. This enables the effective re-entrainment of solid particulate and reduced pressure loss across the catalyst surface.

- Extended boiler availability and increased efficiency

- Checks deposit build-up regardless of boiler operation, changing fuel mixture or varying fuel quality

- Prevents buildup in the air heaters and economizers

- Maximizes thermal efficiency and reduces gas exit temperatures

- Balances heat transfer in the boiler

- Reliable and simple to maintain

- Optimized cleaning with minimal consumption of steam, water and air

Reviews

There are no reviews yet.