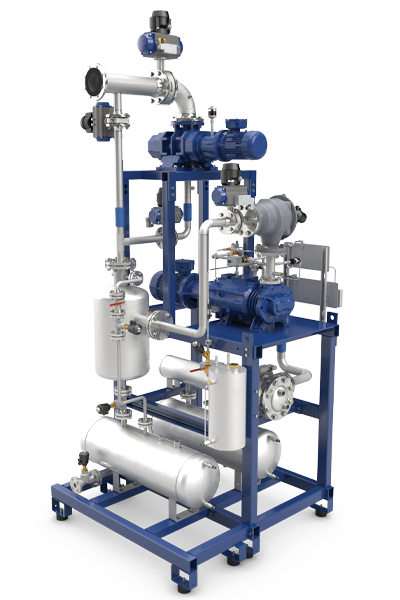

Nash engineers have been designing safe, reliable chemical and pharmaceutical process vacuum systems for decades. Thus, resulting in a well-engineered modular system that guarantees performance and meets your requirements while maximizing flexibility, making it easier to design custom configuration that can be engineered-to-order.

We can quote and ship quickly, delivering in as short as 8 weeks and every vacuum system is reviewed and built to rigorous standards to ensure reliability and safety at all times.

Unparalleled System Performance

- Low cost of ownership – no effluent cost, mechanically efficient

- Environmentally friendly – energy efficient due to lower power consumption in operating range

- Reliable performance – smooth and robust

- Flexible vacuum – any pressure between blank off (0.02 Torr/0.03 mbar) and atmospheric pressure

- Easy to install – integrates with plant controls

- Low maintenance – extended service intervals and bearing life

- System automation – easy integration with plant controls and improves reliability and safety

Handles An Array Of Chemicals

- Adhesives

- Acetates

- Alcohols

- Amines

- Aromatics (BTX)

- Diols

- Ethers

- Ethylene dichloride

- Ethylene oxide

- Fatty acids

- Glycerides

- Hexane

- Halides (HCI/HBr/HF)

- Isocyanates

- Ketones

- MEK

- Methylene chloride

- Mineral acids

- Nitric acid

- Organic acids

- Paraffins

- Pentane

- Phenol

- Phosphoric acid

- Polycarbonates

- Polyglycols

- Polymers

- Sulphides

- Triethylamine

- Tetrahydrofuran

Reviews

There are no reviews yet.