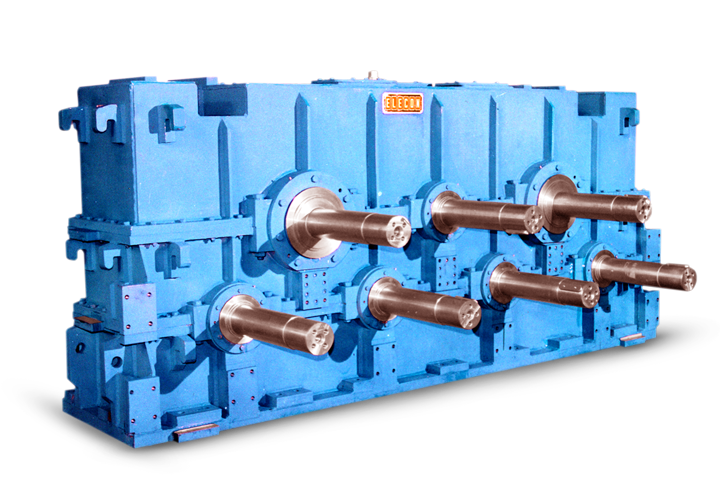

HOT SIZING MILL GEAR BOX

Elecon has developed a special purpose custom built gear box type SBN 2 * 570 – 705 S/SO and supplied to M/s. Jindal Seamless Tubes, Nasik for driving 7 Roll Stand Hot Sizing Mill for Stainless Steel, Pipe finishing.

The gear box is basically designed to transmit power from Two * 340 KW, 750 rpm DC Motor with a reduction ratio of 15.95:1. It consists of twin – double reduction stages having two input shafts followed by cluster of 1:1 ratio gear trains resulting into 7 output shafts which are rotating at the same speeds, but having different direction of rotations.

The gears are made from high tensile carburizing alloy steel, 17 CrNiMo6 as per DIN 17210 case hardened to 60 ± 2 HRC and precisely ground to class of accuracy 6 as per DIN 3961 – 63. The output shafts are made from medium Carbon Steel CK 60 N as per DIN 17200 of adequate size to withstand heavy load transmission for better rigidity without undue deflection.

DESCRIPTION

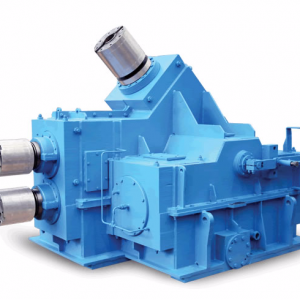

| Features | Helical gear box with 2 input and 7 output shafts |

| Advantages | Heavy Duty gearbox with precise ground gears and multi output shafts |

| Technical Specifications | SBN 2 x 570 – 7 OS S/So |

| Product Application | Seamless Tube Plants for driving roll stands |

| Range | Custom built to client`s specifications |

APPLICATIONS

- Hot Sizing Mill

INDUSTRIES

- Steel Industry

Reviews

There are no reviews yet.