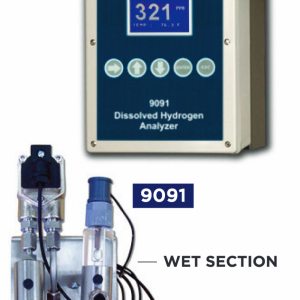

The Waltron 9091 Dissolved Hydrogen Analyzer is the industry standard for continuous measurement of dissolved hydrogen in water. Measurement is microprocessor based and uses a potentiostatic three electrode system.

Important application points include primary loop of nuclear power plants, boiler beed-water in thermal power plants, denitrification of drinking water, and catalytic reduction of oxygen on noble metal surfaces in water treatment plants. The dissolved hydrogen concentrations within the water/steam loop of a power plant gives quantitative and qualitative evidence of the rate of corrosion, corresponding to the buildup or destruction of the protective oxide layer inside pipes and boiler tubes.

Fully automatic remote calibration

Wide range analysis: 0 -1000 μg/L, 0 – 10 mg/L

Automatic temperature and flow compensation

Fast response time (t90 = 30 sec)

No zero point adjustment required

Withstands pressures up to 8 bar (116 psi)

Analog and digital outputs

Low reagent consumption

Minimal maintenance required

Automatic operation

PERFORMANCE

Range

0 – 1000μg/L, 0-10 mg/L

Accuracy

+/- 3 % of reading

Response Time

t90 = 30 sec

Temperature Compensation

Automatic

Calibration

Automatic or manual

Current Outputs

0-20mA, 4-20mA (shunt max 500 Ohm)

Digital Outputs

serial interface RS232

Alarms

flow, calibration, power

Power

100VAC – 240 VAC, 50/60 Hz

SAMPLE DELIVERY OPERATING CONDITIONS

Sample Flow

3 – 18 L/h

Sample Temperature

32-140° F (0-60° C)

Ambient Temperature

32-131° F (0-55° C)

Pressure

0.3 – 8 bar (5 – 116 psig)

Recommended Conditioning

Sample should be filtered to 60 microns

Sample Conductivity

≥ 2μS/cm ; salt cell is required if conductivity is less

MECHANICAL

Dimensions

Transmitter: Height=11” (27.7 cm), Width=7” (17.8 cm), Depth=7.75” (19.7 cm) with wall-mount bracket, Depth = 4.5” (11.4 cm) without wall-mount bracket

Wet Section: Height=6” (15 cm), Width=4” (10 cm), Depth=6” (15 cm)

Download: 9091_brochure

Reviews

There are no reviews yet.