Showing all 12 results

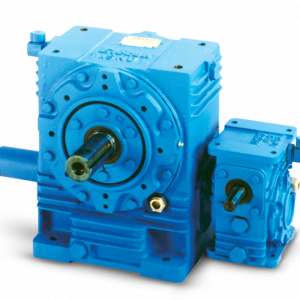

DOUBLE REDUCTION GEAR

DOUBLE REDUCTION GEAR ELECON Double Reduction Worm Gear Units are constructed using two single reduction worm gear units. The primary worm gear unit is specially designed to mount integrally on a standard single worm gear unit which forms the secondary stage. The complete gear unit becomes compact and rigid in

ER SERIES

DESCRIPTION Size 4″ to 17″ Rating 1.1 to 350 kW Mounting and change of Shaft Handling Achieved easily and quickly without dismantling the gear case. Applications Heavy duty stirrer gear units Cooling Tower gear units Double Reduction: Worm-worm, Helical-worm, Worm Geared motors. APPLICATIONS Conveyors Raw Mill Coal Mill Nodulizer Apron

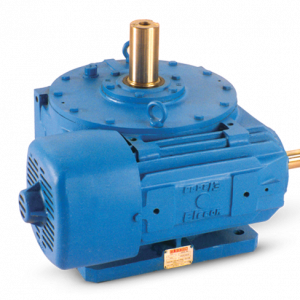

HEAVY DUTY STIRRER UNIT

HEAVY DUTY STIRRER UNIT Heavy Duty Stirrer unit incorporates an extended bearing housing to accommodate a larger bottom bearing and increased shaft size, there by enhancing the unit capacity to absorb the high bending loads imposed during stirrer applications. This gear unit is compact with facility of top mounted pivoted

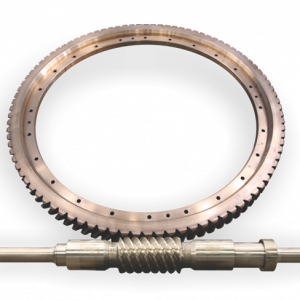

LARGE WORM PAIR BALL MILL

LARGE WORM PAIR BALL MILL Size: 20” to 54” worm pair for coal pulverize mill of coal fired Thermal Power station. APPLICATIONS Conveyors Rotary Kiln Vertical Roller Mill Ball Mills Raw Mill Coal Mill Central Drive Travelling Grate Nodulizer Apron Conveyours Elevator Drives Separator Drive Bulk Materials Handling Classifier Conveyor

Series AJ – Junior Worm Gear

Series AJ – Junior Worm Gear Our series A junior worm gear range is offered in unit sizes 280, 410, 510, 610, 730 and 860 based on a single universal case for each size, giving a high degree of common parts and interchange ability. Features & Benefits Double Reduction Units

Series AM – Mid Worm Gear

Series AM – Mid Worm Gear Our fully metric range of Series AM worm gear units are based on a single universal case for each size, giving a high degree of common parts and interchange ability. Features & Benefits Double Reduction Units (worm/worm) These units consist of a standard single

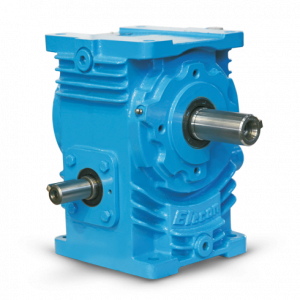

Series BS – Compact Worm Gear

Series BS – Compact Worm Gear Series BS worm gear units have a compact design with high torque capacity. Series BS can be sold as a gearbox or complete geared motor. These units have proven very reliable in tough applications again and again. Features & Benefits Features Benefits Lubricated for

Series ER – Heavy Duty Worm Gear

Series ER – Heavy Duty Worm Gear The ER Series of worm gear units are direct replacements for the David Brown (Radicon) Series A heavy duty worm gear units. All critical dimensions and product quality is the same and the ER heavy duty worm gear range is available in the

SNU MODULAR UNIVERSAL MOUNTING

DESCRIPTION Underdriven SNU-U Overdriven SNU-O Verticle output shaft up/down SNU-V Hollow output shaft SNU-SM Sizes 1 5/8, 1¾, 2, 2½, 3, 3½,4, 5, 6, 7, 8, 9, 10.5 Ratio Min. 5 : 1 to Max 70 : 1 Power Capacity 139 kW APPLICATIONS Conveyors Raw Mill Coal Mill Nodulizer Apron

WORM GEAR HIGHER SERIES

DESCRIPTION Underdriven SFU Overdriven SFO Verticle output shaft up/down SFV Hollow output shaft SSM Sizes 10” to 17” Ratio Min. 5 : 1 to Max 70 : 1 Power Capacity 350 kW APPLICATIONS Conveyors Raw Mill Coal Mill Nodulizer Apron Conveyours Elevator Drives Separator Drive Bulk Materials Handling Classifier Conveyor

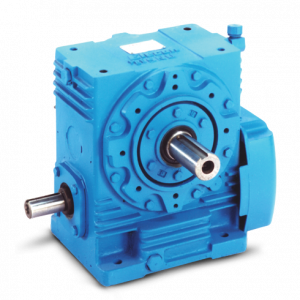

WORM GEAR MEDIUM SERIES

WORM GEAR MEDIUM SERIES DESCRIPTION Underdriven SNU-U Overdriven SNU-O Verticle output shaft up/down SNU-V Hollow output shaft SNU-SM Sizes 4” to 10.5” Ratio Min. 5 : 1 to Max 70 : 1 Power Capacity 139 kW APPLICATIONS Conveyors Raw Mill Coal Mill Nodulizer Apron Conveyours Elevator Drives Separator Drive Bulk

WORM GEAR SMALL SERIES

DESCRIPTION Underdriven SNU-U Overdriven SNU-O Verticle output shaft up/down SNU-V Hollow output shaft SNU-SM Sizes 1 5/8” to 3.54” Ratio Min. 5 : 1 to Max 70 : 1 Power Capacity 12.5 kW APPLICATIONS Conveyors Raw Mill Coal Mill Nodulizer Apron Conveyours Elevator Drives Separator Drive Bulk Materials Handling